Coating System Variations

Indium mirror coating system

Realize plating-like coating Indium mirror coating system

The adopted robots are from two models, LINE DANCER (M-type) and SWAN Pro. We set up everything from spray gun specifications, paint supply systems, and booths to build the system.

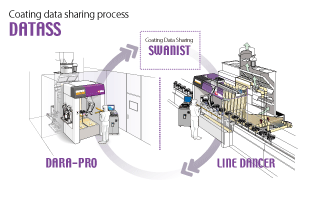

All coating technologies are based on R technology. SWANIST, Takubo's original teaching assistant software, handles operations such as setting conditions.

Robots used Takubo Engineering Original Core technology

SWAN Pro

SWAN Pro 2gun_4top

- SWAN Pro Standard type

SWAN Pro 2gun_4top - Two rings (jigs) are coated at the same time.

- Equipped with a conveyor with high-precision rotation function (4 tops) as standard.

SWAN Pro Turret Gun type 2gun_4top

- Turret Gun unit is attached to the tip of the robot.

SWAN Pro 2gun_Turret Gun/Turret Gun 4top - Compensate for areas that are difficult for the spray gun to reach, such as the inside of workpiece rings.

- Two guns are mounted in one unit to accommodate two colors.

- ※Workpiece is a reference image

- Oil booth is used as a booth

LINE DANCER

Explosion-proof coating robot LINE DANCER 8Top

Equipped with conveyor with rotating mechanism, W-turn 8top. Four workpieces are coated at the same time.

Separated from the continuous conveyor line, the handling robot is responsible for transferring the product.

Coating production can be performed without contaminating the conveyor line.

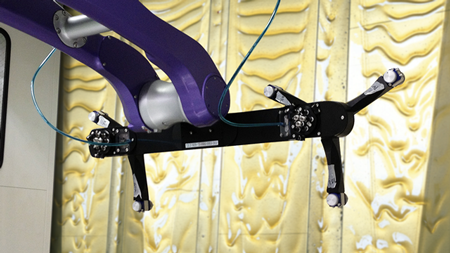

Robot arm LINE DANCER

- Original explosion-proof motor used

LINE DANCER Robot arm Small explosion-proof motor type CG - Payload 20kg

Robot arm capable of carrying up to 16 guns - Suspended 4-axis robot arm

It minimizes coating space and enables coating production at maximum performance with multiple guns.

Turret Gun Three Gun Type LINE DANCER

- Three Gun Type

Three Gun Type - Compatible with three coats

Color change by revolving gun attachment - Covers the backside of workpieces and the inside of revolving workpieces

For coating areas that sprayers cannot reach. - One robot can do 3 coats

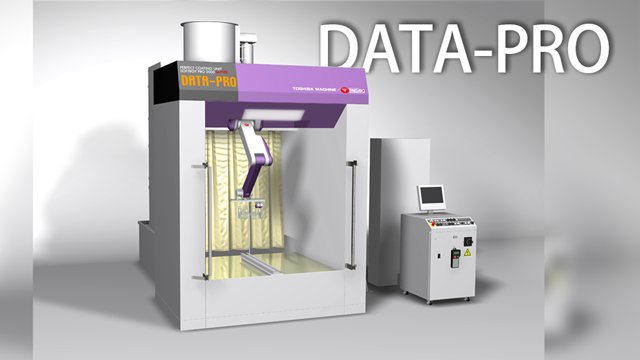

Robot dedicated to coating data creation DATA-PRO

DATA-PRO

DATA-PRO is a coating robot dedicated to coating data creation.

This is a coating robot developed exclusively for coating tests, condition settings, coating test data, and various workpiece information, including teaching data, test condition settings, and coating plate samples.

In addition to coating testing, the robot can be used to train robotics personnel.

Robot dedicated to coating data creation DATA-PRO

- Coating robot dedicated for condition setting

- Eliminates coating tests on the production line, thus eliminating unnecessary time loss for coloring

- The standard teaching assistant software SWANIST performs condition setting and coating tests and transfers the coating data to the SWAN Pro and LINE DANCER robots on the main production line.

- Reproducibility is high, and simple positional adjustments can reproduce the coating data, allowing conditions for coating to be set without stopping the main production run.

Stabilization of quality

- Eliminates quality inconsistencies at factories scattered throughout the country

Stabilization of quality - Avoids any diversification production risk

Paint supply systems

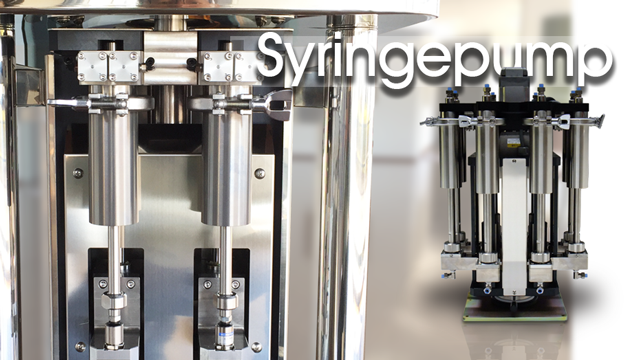

Syringe pump

Controllable in 1cc increments. To make μ units of the discontinuous thin film possible, a precise feeding device is essential. This is the critical heart of coating that reproduces μ film with the robot and spray condition settings.

※DataPro is not included in the standard In. Mirror Coating System

Mechanisms for easy maintenance

- Easy to disassemble and maintain

Disassembly Maintenance Syringe pump - Easy to clean

Cleaning time is greatly reduced by adding a cleaning device

Improved workability

Systematized paint supply system

- Precise control of paint with advanced control

Paint supply system Installation example - Systemization, including color change systems and system cleaning equipment.

- Pearl and metallic paints are also possible

- Water-based paints are also available

- ※Indium paints use a dedicated indium circuit.

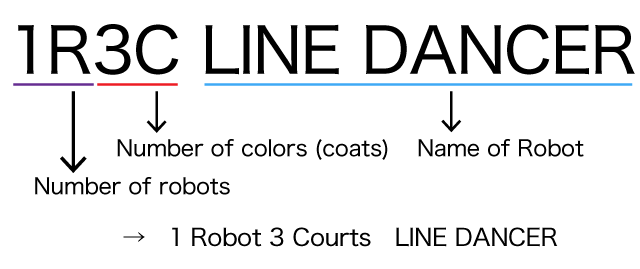

System name

Explanation of system name

The number of robots, number of courts, and robot brand names are shortened and classified as system names for easy understanding.

The number of coats in 3C has the same meaning as the so-called gun number. A three-coat system with one gun is possible, but it takes some time for the color change system and cleaning, so we have adopted the Turret Gun, a multi-gun attachment developed in-house, to increase production volume. This system is capable of multiple coats with one robot.

→Multiple gun attachment

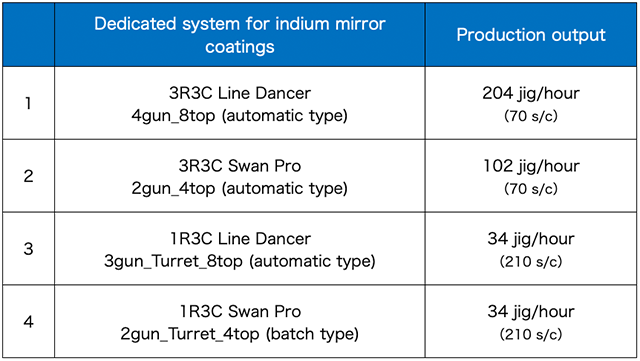

Standard system Four types

Indium mirror coating system has a standard lineup of four types, including batch type and automatic type, according to the target production volume, quality, installation space, and production style. In addition, if topcoat specifications are changed in the design, or if a five coat system is used, the system will be customized from this standard system.

1. 3R3C LINE DANCER 4gun8top Automated coating system

One robot is in charge of one coating, and the coating system consists of three robots in total.

It is designed for mass production with short travel time and high productivity.

- 3R3C LINE DANCER4gun8top Automated coating systems(for mass production)

- One robot with four guns Conveyor (table) 8top

2. 3R3C SWAN Pro 2gun4top Automated coating system

Three robots process three coats (one color per robot). This is a compact type semi-mass production system for plating-like coating.

SWAN Pro is a standalone robot, and the transfer is handled by a double-turn with a revolving device mounted on SWAN Pro. Co_SWAN, a coated material handling system, is detached from the conveyor and handles the handling of the coated material, keeping the line clean and preventing coating defects such as spattering.

- 3R3C SWAN Pro2 Gun 4 Top Automated Coating System(for semi-mass production)

- One robot with two guns Conveyer(table) 4top

3. 1R3C LINE DANCER Turret 3Gun 4top Automated coating system

One robot process 3 coats (3 colors per robot). This is a production line for plating-like coating in small quantities and for a wide variety of products.

It is equipped with a Turret Gun unit that can be attached to three guns for speedy color changes.

It is a compact coating system.

- 1R3C LINE DANCER three gun turret four top automated coating system (for small-lot, high-mix production)

- Three guns on one robot Conveyer(table) 4top

4. 1R3C SWAN Pro Turret 2Gun 4top Batch type coating system

This is a batch-type coating system in that one robot processes three coats (three colors per robot). After each coat is processed, the worker carries the workpieces to the drying oven. Initial costs are also reduced.

- 1R3C SWAN Pro 2Gun Turret 4top Batch type coating system(for small-lot, high-mix products)

- Two guns on one robot Conveyer(table) 4top

Production Volume Performance

Indium mirror coating system is designed from 4 standard types.

- The Indium mirror coating system can be used for batch coating with human intervention or automated systems for mass production.

- You can choose from a variety of options based on your target production volume and installation space.

- We will design it taking into consideration the target production volume, number of coats, and other factors.

- For mass production or distributed production in various locations, we also offer DataPro, a robot dedicated to data creation.

Data Pro: This is a dedicated condition-setting robot that eliminates the need for condition-setting and coating tests on the production line.

For inquiries

For inquiries, please visit our Contact Us page.

Indium mirror coating system Catalog Material Link

Indium mirror coating system Catalog MaterialLink to product page

A4 8page Catalog

Indium mirror coating system Leaflet MaterialLink to product page

A4 2page leaflet